Outboard engine carburetor maintenance and maintenance

2024/04/08 17:29

The carburetor is a mechanical device that mixes and atomizes fuel and air in a certain proportion during engine operation.

We know that engine operation requires three major elements: air, fuel, and ignition. These three burn in the cylinder to generate power. In order to ensure complete and rapid combustion, it is necessary to premix air and fuel in proportion before entering the cylinder to form Mist fuel, the device that undertakes the task of premixing, is the carburetor.

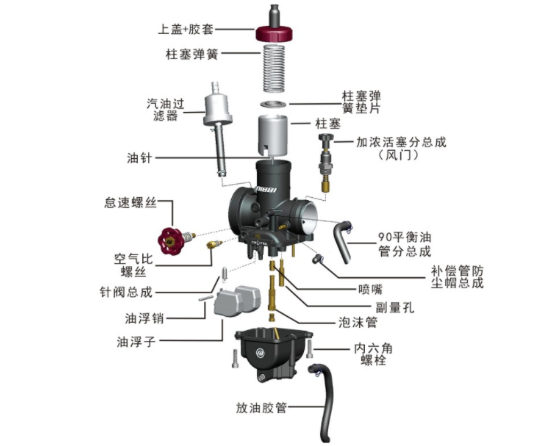

Figure 1 A two-stroke engine carburetor

From the above description and pictures, we can know that the carburetor can be simply regarded as a "three-way pipe", which takes in air (damper) all the way, fuel (oil circuit, fuel pump) all the way, and outputs mixed mist fuel all the way.

Features of 2. outboard engine carburetor

Compared with other fire rescue equipment, the two-stroke outboard carburetor has two obvious characteristics. One is that the air inlet (air door) has no air filter, which is to prevent the air filter from absorbing water and damp and inputting humid gas to the engine. The second is that the outboard engine used for water rescue has a greater risk of falling into water, so it is necessary to study its drainage operation method.

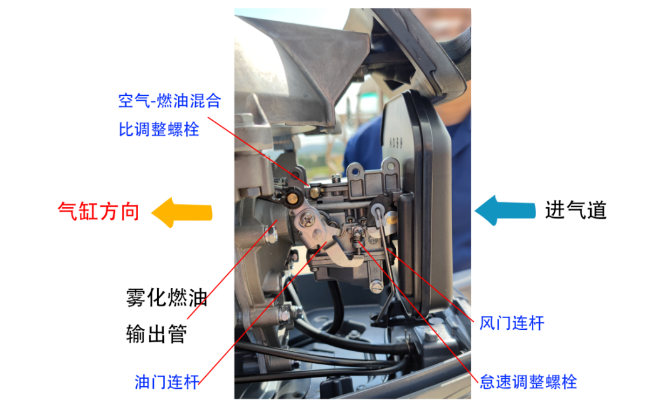

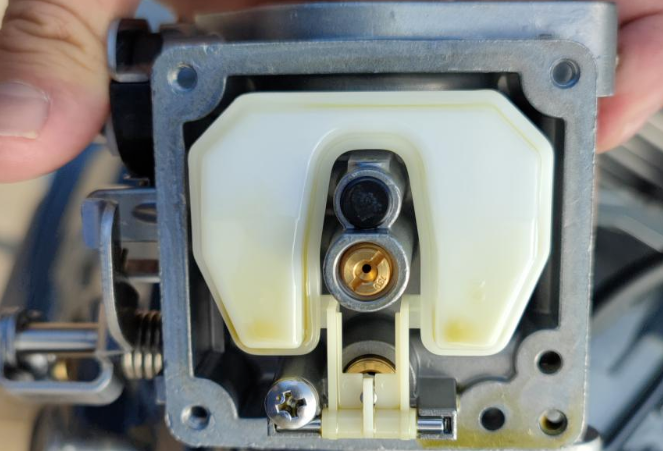

Figure 2 Carburetor for outboard motor

It can be seen from Figure 2 that the carburetor is not only responsible for a simple "carburetor" function. In fact, it is a "logistics support center control panel" serving the cylinder. It "feeds" the cylinder with appropriate fuel and air. Through it, the idle speed can be adjusted (in fact, the minimum opening angle of the throttle valve of the atomized fuel output pipe is adjusted), and the air-fuel mixing ratio can be adjusted. At the same time, the role of the throttle and throttle is also reflected by the carburetor.

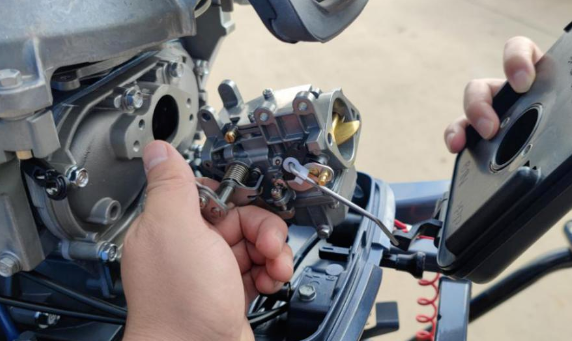

Fig. 3 Disassembly diagram of carburetor

It can be clearly seen from Figure 3 that the carburetor is connected to the two major components of intake and combustion, and the carburetor is in the middle position.

3. carburetor water emergency maintenance

As mentioned above, the outboard aircraft used in water rescue has a great risk of falling into the water, so it is of practical significance to deal with the emergency of the outboard aircraft. For the overall emergency treatment of the outboard motor, please refer to the article "Gankun (2) in the cylinder" before this public number. Here, only the carburetor inlet water treatment is introduced.

After the outboard engine falls into the water, the water will quickly enter the carburetor along the intake duct, and then enter the oil circuit and cylinder. Therefore, the carburetor is the "severe disaster area" and "flood storage area" for the water intake, and the drainage efficiency is high at the carburetor position., The effect is good.

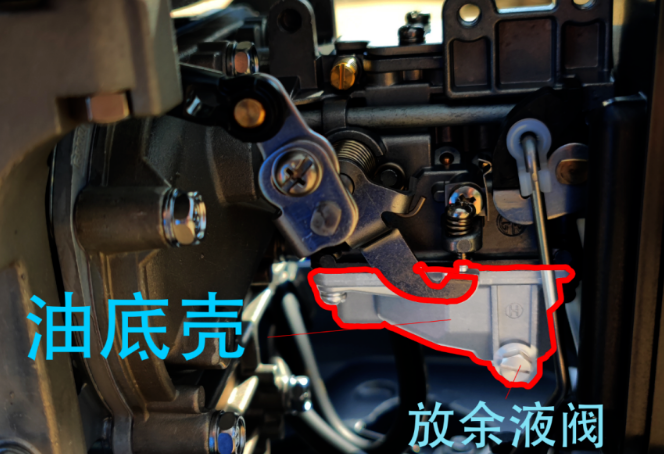

The oil pan of the carburetor itself is equipped with a drain valve, which can be used to drain water after entering the water.

Figure 4 Carburetor sump and drain valve (external)

Fig. 5 Oil Pan Disassembly

Figure 6 The internal structure of the carburetor

After the outboard motor falls into the water, before pulling the start rope to drain the water, you can use a screwdriver to loosen the drain valve (Figure 7). At this time, pull the start rope to drain the water, the drainage efficiency will be improved, and it will also help drain sediment impurities, which is conducive to emergency maintenance and start-up.

Fig. 7 Loosening the drain valve

It should be specially stated here that in the implementation of emergency maintenance in the water rescue environment, safety should be the first priority, and the carburetor should be dismantled for faults such as outboard aircraft falling into the water. the carburetor should be handled only by loosening the drain bolt and draining water according to the method shown in fig. 7. Fig. 3 Disassembly diagram of carburetor

It can be clearly seen from Figure 3 that the carburetor is connected to the two major components of intake and combustion, and the carburetor is in the middle position.

Emergency maintenance of 3. carburetor water ingress Figure 3 Carburetor disassembly diagram Figure 3 Carburetor disassembly diagram It can be clearly seen from Figure 3 that the carburetor is connected to the two major components of intake and combustion, and the carburetor is in the middle position

中文简体

中文简体 ENGLISH

ENGLISH Русский язык

Русский язык